Introduction to Machine Vision

Machine vision is a rapidly evolving technology that combines computer science and engineering to enable machines to interpret and understand visual information from the surroundings. By utilizing cameras and sophisticated algorithms, machine vision systems can perform functions that historically required human observation and analysis. This technology is increasingly vital in various industrial applications, from quality control to autonomous navigation. For a comprehensive overview of machine vision, you can explore more at machine vision.

What is Machine Vision?

Machine vision refers to the technology and methods that allow computers and systems to interpret visual data. This technology involves the capture of images through cameras, the processing of these images by software, and the analysis of visual information to make decisions or take actions. Machine vision integrates various components, including imaging sensors, lighting, and software algorithms, to automate and enhance several processes across numerous industries.

The Importance of Machine Vision in Industry

Machine vision plays a critical role in industries such as manufacturing, packaging, healthcare, and robotics. Its importance can be attributed to several factors:

- Quality Control: Machine vision systems can identify defects or inconsistencies in products, ensuring only high-quality items reach the market.

- Automation: By automating visual inspection and data analysis tasks, machine vision reduces labor costs and increases efficiency.

- Data-Driven Decisions: Machine vision generates valuable data on production processes, enhancing decision-making capabilities and fostering continuous improvement.

In summary, machine vision is not just a tool; it is a transformative technology driving operational excellence in many sectors.

Core Components of Machine Vision Systems

A machine vision system comprises several key components that work together to enable visual data processing:

- Cameras: Cameras capture images and varying types of sensors are designed for specific applications, such as high-speed cameras for fast-moving items or 3D cameras for depth perception.

- Lighting: Proper lighting is essential for capturing the best possible images. Different lighting setups such as backlighting, front lighting, and diffuse lighting can significantly affect image quality and analysis.

- Processing Hardware: This includes CPUs and GPUs that are capable of real-time image processing. Specialized processing units may be utilized for frame grabbing and image analysis.

- Software: The software is responsible for image processing tasks including filtering, pattern recognition, and measurement. It often includes machine learning algorithms to improve accuracy and adaptability.

Applications of Machine Vision

Quality Control and Inspection Processes

One of the primary applications of machine vision is in quality control. In manufacturing, machine vision systems inspect products for defects at rates no human quality control agent could match. For instance, in the automotive industry, machine vision systems are used to examine components for structural integrity and dimensional accuracy. By employing advanced imaging techniques, these systems can detect micro-level defects that are imperceptible to the naked eye, ensuring only products that meet stringent quality standards are approved for distribution.

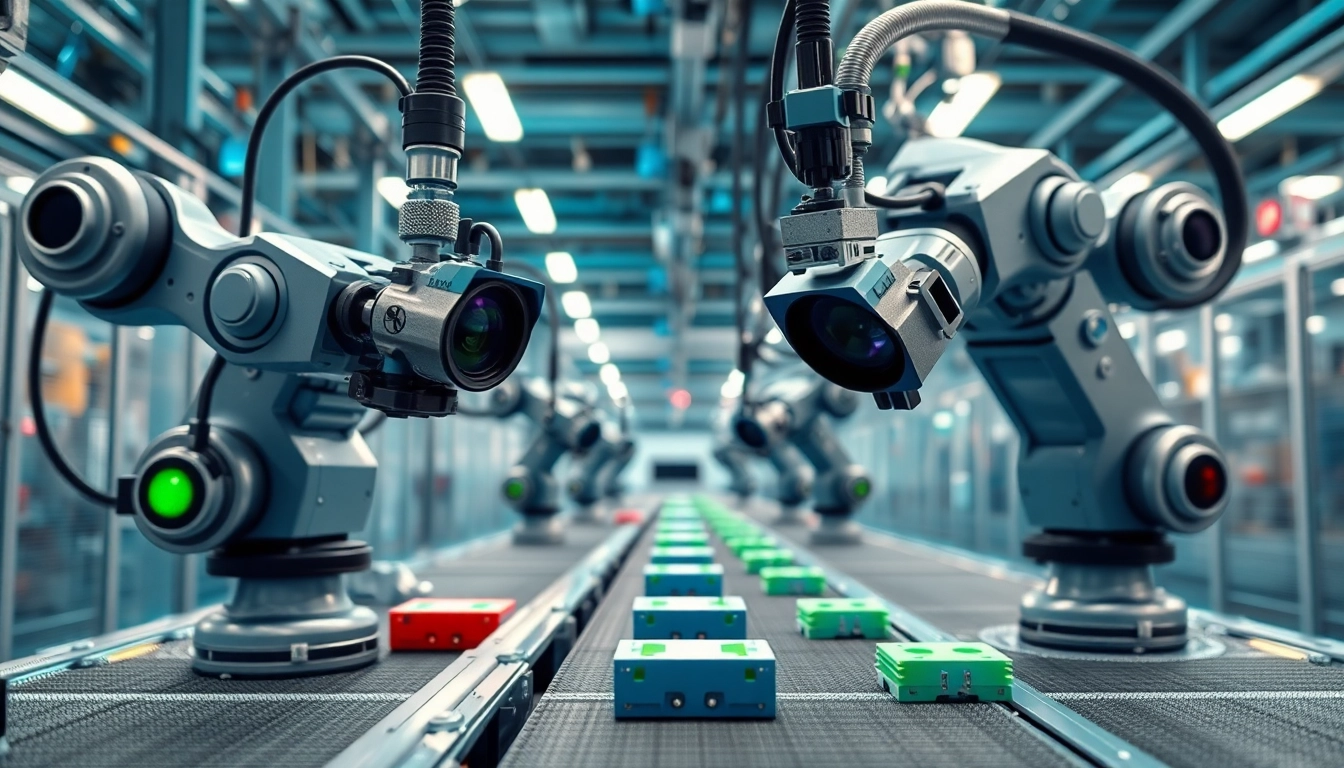

Machine Vision in Automation

Machine vision enables automation in many industrial processes by facilitating tasks such as sorting, guiding robotic arms, and tracking items within a production line. For example, in packaging, machine vision systems can identify the correct placement of labels and ensure the integrity of seals. This significantly enhances the speed and reliability of packaging workflows, reducing the risk of human error and operational downtime.

Case Studies: Successful Implementations

The effectiveness of machine vision is highlighted in various case studies. In pharmaceuticals, machine vision systems have been implemented to ensure that labels and batch numbers on medication containers are printed accurately, preventing costly recalls and ensuring compliance with regulatory standards. Similarly, in food processing, machine vision helps detect foreign objects, ensuring food safety and quality, which is paramount for consumer trust.

Technical Aspects of Machine Vision

Cameras and Sensors in Machine Vision

The choice of camera and sensor technology is pivotal in a machine vision system. The types of cameras utilized may include:

- Line Scan Cameras: Best used in high-speed applications such as conveyor belts where continuous scanning of a product is necessary.

- Area Scan Cameras: Suitable for capturing static images at various angles and distances, ideal for objects on assembly lines.

- 3D Vision Systems: Utilize depth perception technology to identify objects’ shapes and contours, essential for applications requiring spatial awareness.

Software Solutions for Image Processing

The software used in machine vision systems includes various capabilities such as image preprocessing, analysis, and decision-making algorithms. Advanced software platforms may incorporate machine learning and artificial intelligence to dynamically adapt the analysis process based on the characteristics of the visual data, improving the system’s accuracy and reducing false positives during inspections.

Data Analysis in Machine Vision Systems

Machine vision is not merely about capturing images but also about interpreting and analyzing the visual data collected. Data analysis involves transforming raw images into actionable insights through feature extraction, classification, and measurement. This analytical capability allows industries to enhance quality control processes, optimize production lines, and increase overall operational efficiency.

Challenges in Implementing Machine Vision

Common Obstacles and Solutions

Despite its numerous benefits, implementing machine vision systems can pose several challenges:

- Environmental Variability: Changes in lighting, object characteristics, or backgrounds can affect system performance. Solutions include using adaptive lighting and image preprocessing techniques to standardize input conditions.

- System Complexity: The integration of machine vision systems can lead to complexity in setup and calibration. Simplifying system architecture and utilizing user-friendly software can ease these challenges.

- Employee Resistance: Employees may resist transitioning to automated systems. Training programs and showcasing the benefits of machine vision can facilitate smoother transitions.

Integration with Existing Technologies

Integrating machine vision with existing manufacturing technologies, such as robotics and conveyor systems, is vital for maximizing efficiency. It is essential to ensure compatibility and to upgrade infrastructure where necessary, which often involves integrating various sources of data into a unified platform for seamless operation.

Addressing Cost Concerns

While initial investment costs for machine vision systems can be substantial, the long-term savings in labor costs and the reduction in errors often justify the expense. Businesses should conduct a thorough cost-benefit analysis to understand the return on investment and to identify gradual implementation strategies that allow for budget distribution over time.

The Future of Machine Vision Technology

Emerging Trends and Innovations

The field of machine vision is rapidly advancing, with several trends shaping its future. In particular, the integration of artificial intelligence and machine learning is paving the way for more advanced algorithms that enhance image recognition accuracy and speed. The emergence of 3D machine vision and deep learning methods is also transforming inspection processes, allowing machines to learn from previous outcomes and improve over time.

The Role of AI in Machine Vision

Artificial intelligence plays a pivotal role in enhancing the capabilities of machine vision systems. AI algorithms can analyze vast amounts of visual data far faster and more accurately than traditional methods. They can identify patterns, predict failures, and facilitate process optimizations, making the technology exceptionally potent across industries. For instance, in the automotive sector, AI-driven machine vision systems can assess the quality of complex components in real time, ensuring higher standards of safety and efficiency.

Predictions for Machine Vision Growth and Adaptation

The growth of machine vision technology is poised to accelerate, spurred by increased demand for automation and quality assurance across various sectors. With the continuous development of smaller, more efficient hardware and advanced software algorithms, machine vision will likely become even more accessible and widely adopted. Additionally, as industries explore sustainability and efficiency, machine vision will become an indispensable part of operational strategies, driving innovation and enabling manufacturers to remain competitive in a rapidly evolving marketplace.